Logistics and supply chain brought the arguably most important innovation of the 20th Century – the standardized container. This invention of the 1960ies allowed producers to ship much more goods for a far cheaper price over long distances. So much more and so much cheaper that it single handedly created globalization and the world as we know it. Without that unassuming piece of metal, we’d not have smartphones, the infrastructure for the internet, cameras and in general the wealth that was generated in the latter half of the previous century.

“If you think there is no way, we will find one”

We asked Mario Hess, Global Head of Customer Solutions from the logistics company deugro (the subtitle is their motto) to take us into his world and show us how blockchain could dock to it. Block- and Supply- share the word “chain” for a reason as Mario explains: “Before the banana, harvested in Central America lands into your belly, it has gone through a lot of hands. It starts with a producer who sells it to a distributor.”

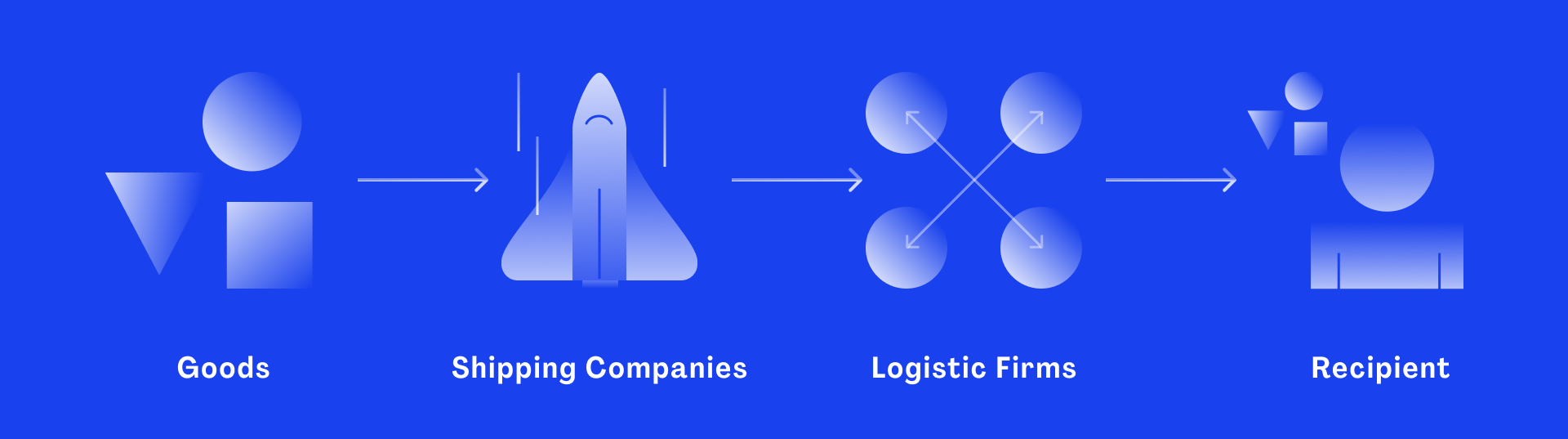

That is the one we know from the banana boxes we all love from the last time we moved into a new apartment. “Between the two parties are shipping companies that transport the goods, logistic firms that make sure that the product arrives on time and in shape. There are ports, customs offices and local transport firms.”

The complexity becomes even more obvious in deugro’s core business. “Deugro delivers high value freight such as engines for nuclear power plants. We bring goods to places where there are no roads. We build roads if it has to be.”

The supply chain has to guarantee that the engine arrives in perfect condition, at the right place in time, it has to navigate laws, customs and the sum of all bureaucracies of the world. “If that engine arrives late, the complete production might halt which could result in millions of cost” says Mario Hess and he adds:

“A blockchain could help to verify the authenticity of all documents, for instance the bill of lading. It could support or replace current forms of certification.” It could also verify “stuff” that we customers want to have – such as the authenticity of luxury goods or to guarantee that there is only tuna in the can. And not also a dolphin.

These wonderful promises made us do some research to find successful blockchain solutions in supply chain and logistics. It turns out that nearly all of the ones we found were either silent or could be classified as failure.

Transparency spoils an opaque business

Occasionally, the best blockchain solution fails when it meets a cruel world. Here follows an (unproven) story a product manager relayed to us. At the end of the story it will be clear why that person’s name is not revealed. A few years back, a huge digital consulter and tech company, being both Big and sporting the brand color Blue implemented a blockchain-based supply-chain solution for one of the biggest global shipping companies whose name sounds like a cupboard from a Swedish DIY-furniture store.

The objective was laudable: A manufacturer demands good from a producer situated on the other side of the world. The goods are stored, transported, put through customs, transported again, more customs, stored again, transported again until it reaches its destination. It is in the interest of most of the participants in that chain that the goods arrive in time and shape and in a cost effective way.

A blockchain is a great solution – in theory – for this process. Its immutability makes it extremely difficult to falsify the data trail that travels along the goods on their global journey. Not even the owner of the digital supply chain – the shipping company – can wreak havoc, this transparency is a nice side effect for an industry that has to deal with opaqueness.

The system would reveal where a particular item is at any given moment, who has control for how long and what money is paid en route. The last part is where the beautifully implemented technical solution fell apart as the former PM describes. The system would require the recipients of the bribes – which are common business practice for a shipping business to have cargo stored, cleared and transported – to be documented in an infallible, incorruptible software. The conundrum is evident.

And so this glorious project fizzled out like an air mattress, not with a bang but with a whimper.

When asking ChatGPT to summarize why that particular project failed, it gives an answer that makes the reader chuckle, knowing what the PR-speak actually means: “While the implementation gained support from several shipping companies and port operators, achieving widespread adoption has been challenging. Some industry players were hesitant to join due to concerns about data privacy, integration complexity, and the potential dominance of a single platform in the industry.”

Choc shock block for block

Here is another story the author witnessed. The average US-American eats 40 bars of chocolate every year. The Swiss double that number which is easy to believe – they make some of the best Chocs in the world. While recipes vary, the one key ingredient for a good chocolate is cocoa beans. The more of that natural resource is used and the higher its quality, the more yummy.

Cocoa beans like it hot, they are mainly grown in West Africa and Latin America. 90% of the crops are grown and harvested by smallholder farmers. Since the world’s appetite seems to grow boundless but bean fields can not, the price for Cocoa has grown by 50% in the past 10-15 years.

Most consumers don’t care much how Cocoa is grown, how fair the farmers are paid or how qualitative the beans are – as long as their daily dose of chocolate fills the cavities of their sweet tooths. But there is a growing demand for a fair-trade, high-end product. These consumers are ready to pay a premium for taste and conscience. However, there are not enough beans in the world to satisfy this demand. We have learned from a development agency that German and Austrian chocolate producers wage fierce economic battles in countries such as Nicaragua – including comical colonial-like visits by wealthy company bosses to not-so-wealthy farmers – to grab the few profitable contracts with fair and ecological sustainable bean growers.

What’s blockchain got to do with it? Trust! If you pay a premium for a bean you want to make sure that it is an original. The chocolate producers from the Northern hemisphere have an incentive for proof – they don’t want to be caught buying bad beans for prime choco. The high quality farmers have the same incentive since cheaply made knockoff beans would dilute the price they can get for their top crop.

But between the farmer and your mouth is a long chain and a plethora of potential bad actors that would want to inject bags of cheap second-rate cocoa and sell it for top dollar. That requires collusion by crooked certification bodies, transport firms, customs agents (maybe the same that received bribes in the story above) and they can only operate in the shadow of untraceable and ever-changeable data.

That’s where blockchain comes in. Qualified farmers are identified by the producer and their ID is put on the blockchain. If an unqualified producer was to get into that database, the blockchain’s transparency would make it visible. The farmers receive quotas. The blockchain’s immutability doesn’t allow a simple and undetected change of the quotas if someone plans to mix cheap and good beans. The farmers receive RFID chips with which they tag their bags of brown gold, they are scanned on every step in the way and are immediately traceable.

Transparency, immutability and traceability are key concepts in blockchain. Combined they can create something that is barely possible off chain – trust without having to trust humans.

Now, most of the above described processes could be implemented with a simple database. Blockchain however reduces one more threat vector – the owner of the supply chain. The chocolate producer owns the supply chain. In a regular database, some employees can change data, add quotas, add new qualified farmers even though they are not certified. In a business where trust in a product’s quality and originality is key, prohibiting the data owner to change the data can create that extra level of trust.

So, where is the catch?

The technology is straightforward. But the reality that it supports obviously isn’t. Mario Hess from deugro explains that their own involvement with blockchain has purely been theoretical. He sees the advantages but also the blockers.

“One hurdle that we are dealing with is the state of digitalization in the chain. You wouldn’t believe how much paper is still produced to ship goods from A to B. Then you’ve got jurisdictions like Brazil, whose customs demand printed paper, manually stamped and signed in blue ink. We work for a Japanese producer that bakes-in RFID chips into their products. This is great, since the chain starts digital. We certainly need more digitalization in conjunction with tech like RFID for blockchain solutions to be of better use.”

It also pays to look into the business incentives for a new technological solution. The supply chain is not controlled by a single company, it is highly fragmented. Producers have some incentive to prove authenticity and quality, distributors could better market proven quality, shipping companies could run their operations more efficiently.

However, one of those stakeholders would have to shoulder the bulk of the investment into blockchain and especially into the rollout. As Mario Hess points out, that isn’t so easy in these times. “When a shipping container would cost you $4,000 to transport before Covid, that price climbed up to $90,000 during the pandemic. Companies had to put all their financial resources into shipping. Then there wasn’t much left for investing into a technology that improves efficiency.”

Reality check for blockchain in logistics

That last part is a reality-check for blockchain in supply chain and logistics. As Mario Hess puts it: “The greatest innovations that happened in my 26-years in the industry were vessels like the Emma Maersk that can carry 11,000 containers and the automatization of freight terminals. This is what I would call ‘super’. Blockchain as a technology can improve our industry incrementally, it makes our industry as Germans would say ‘super duper’. Blockchain is the ‘duper’ on top.”

What it really takes for blockchain to break into logistics is Mario Hess’ final word: “The drive comes from the customer side; we need to tie blockchain into direct produced savings. Savings can be produced by increased productivity or decreased cross-validation.”

We set out to make this happen.